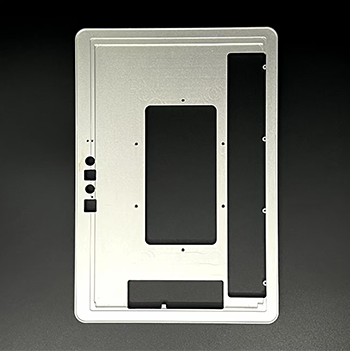

Aluminum material

Solution

Solution

Aluminum is a material that is often used in the stamping industry due to its properties and the fact that it can be utilized in multiple industries. Its qualities make it an easy material to process in many different applications.

Quote Inquiry >

Aluminum Properties

Due to its many advantages, aluminum stampings are a common choice across a wide range of applications. These advantages stem from aluminum's unique properties and the economical stamping process. Here are the key advantages:

- Lightweight: Aluminum is significantly lighter than many other metals, such as copper or steel, resulting in lighter products and assemblies overall.

- High strength-to-weight ratio: Despite its low weight, aluminum possesses exceptional strength, especially when alloyed with other materials.

- Cryogenic adaptability: Aluminum is well-suited for use in cryogenic conditions because it maintains its durability at low temperatures, unlike some metals that can break easily.

- Electrical and thermal conductivity: Despite its resistance at low temperatures, aluminum also conducts heat and electricity well, making it useful in power systems, electrical enclosures, and heat sinks.

- Affordability: Aluminum is more readily available and less expensive than other metals, such as copper or titanium.

- Visual appeal: Aluminum is attractive in consumer products and construction because it can be anodized, polished, or coated to create a high-quality finish.

Industry Applications

Our mission is to provide best-in-class metal stamping and metal forming solutions for the most challenging and innovative engineered product designs. We serve a wide range of market sectors by combining advanced metal stamping production and tooling equipment, superior quality control, seamless automation and production processes, and a knowledgeable and experienced team.

- Aerospace

- industry

- ocean

- medicine

- Construction

- car

- illumination

- Electronics

Precision Stamping, Smart Manufacturing for the Future

Your one-stop metal stamping solutions expert

Your one-stop metal stamping solutions expert

Quality assurance

Quality is our top priority. We conduct a feasibility review at the beginning of each project to ensure the manufacturability of the part. A full-speed run study is also performed during the first production run to ensure quality before mass production. This enables our quality and production management teams to closely monitor control measures to ensure a smooth production process. Once testing and inspection pass and the first batch of qualified parts are produced, production continues.

Our quality management system consists of advanced quality technology and controls, a continuous improvement program, and an exceptional quality laboratory and management team. We deploy camera vision systems and sensor technology in our production facilities, designing and manufacturing unique systems for each production project. Our vision system technology works in harmony with our stamping production machinery, thoroughly inspecting and identifying part features and dimensions through automated camera imaging. This quality control process ensures that every part produced using our stamping equipment is 100% qualified and defect-free.

Power your applications more efficiently with high-performance busbars. With a dedicated team, innovative equipment, and superior quality control, we provide high-quality services tailored to each customer's unique needs.

Our quality management system consists of advanced quality technology and controls, a continuous improvement program, and an exceptional quality laboratory and management team. We deploy camera vision systems and sensor technology in our production facilities, designing and manufacturing unique systems for each production project. Our vision system technology works in harmony with our stamping production machinery, thoroughly inspecting and identifying part features and dimensions through automated camera imaging. This quality control process ensures that every part produced using our stamping equipment is 100% qualified and defect-free.

Power your applications more efficiently with high-performance busbars. With a dedicated team, innovative equipment, and superior quality control, we provide high-quality services tailored to each customer's unique needs.

Stamping products

Explore other materials

English

English 中文

中文