Technology and Process

Progressive die medium speed stamping

Our stamping department utilizes presses to stamp copper, aluminum, iron, and other metals at speeds of 30-120 strokes per minute, depending on product requirements. This speed enables rapid delivery of multi-million-piece projects. Metal materials are stamped continuously at a steady speed, operating in multiple stations to provide cost-effective parts to our customers. Stamping features include automatic in-die assembly, bimetallic, punching, spring pins (eyelets), countersunk, critical dimensions, embossing, small holes, flats, forms, inlays, multiple punches, numbering, trimming, tapping, threads, and end stamping.

We provide efficient, quality-oriented tooling, utilizing advanced equipment, efficient management, skilled technicians, and knowledgeable designers to offer a variety of metal stamping services for diverse market sectors. Our in-house tooling shop enables us to craft precision progressive dies for production stamping, ensuring the most efficient solutions for even the most complex tooling requirements and intricate part designs. The industries we serve include wall switches, home appliances, auto and motorcycle parts, mobile track sockets, electrical equipment, electronic lighting, luggage accessories, solar energy, exterior wall steel structures and smart locks.

Quote Inquiry >

We provide efficient, quality-oriented tooling, utilizing advanced equipment, efficient management, skilled technicians, and knowledgeable designers to offer a variety of metal stamping services for diverse market sectors. Our in-house tooling shop enables us to craft precision progressive dies for production stamping, ensuring the most efficient solutions for even the most complex tooling requirements and intricate part designs. The industries we serve include wall switches, home appliances, auto and motorcycle parts, mobile track sockets, electrical equipment, electronic lighting, luggage accessories, solar energy, exterior wall steel structures and smart locks.

Precision stamping process

With advanced automated stamping equipment and mature process technology, we ensure the high precision and high consistency of each metal stamping product.

Automated production

The use of intelligent production lines and optimized processes can greatly improve production efficiency and reduce energy consumption and material loss.

Multi-industry adaptation

Covering multiple fields such as wall switches, home appliances, auto and motorcycle accessories, smart locks, etc., the design and production can be flexibly adjusted according to customer needs.

Continuous innovation

Guided by user experience, we continue to develop new stamping technologies and material applications to quickly respond to market changes.

Material

While each metal has its own unique mechanical, chemical, and surface properties, our knowledgeable engineering and production teams have decades of experience in achieving the best results from a wide range of metals. Our team develops the correct tooling techniques to ensure that the unique characteristics of any metal perfectly match the customer's requirements for their metal stampings. The types of materials we typically process include:

Our production parts

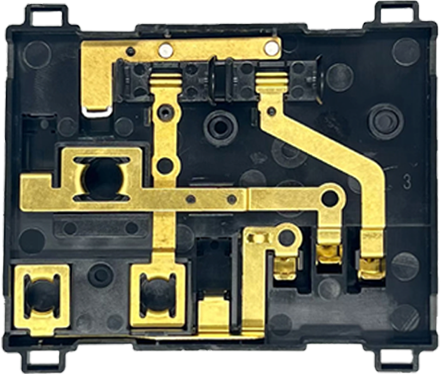

We produce a wide range of precision die-cut, high-speed metal stamping parts made from copper, precious metals, and ferrous metals. We specialize in manufacturing precision electronic connectors, smart locks, and non-electronic components that are used in some of the world's most popular consumer goods and essential products.

Since 2014, Qingmin Company has owned and operated, designed and manufactured molds, and mass-produced a wide range of custom precision metal stamping parts using progressive dies for high-speed stamping, including:

• Wall switch copper parts: British, American, Australian, South African, European, and Italian series

• Home appliances: heat sinks, supports, and neutral/live contacts for various small appliances

• Mobile track sockets: A complete range of track socket and adapter parts

• Auto and motorcycle accessories: Seat connectors, brakes, and other parts for cars and motorcycles

• Electrical equipment: Factory high and low voltage cabinets, surge protectors, and low-voltage boxes

• Electronic lighting: Electronic components, electronic connectors, indoor and outdoor lighting

• Luggage: Home luggage, storage cases, lawn mower strap buckles, and luggage corner protectors

• Solar: Photovoltaic mounts, solar panel connectors, retaining washers, and rust-resistant rails

• Exterior steel structure: Exterior steel structure pendants made of aviation-grade materials

• Smart locks: smart lock accessories, single tongue locks, drawer locks, ball lock bodies

Since 2014, Qingmin Company has owned and operated, designed and manufactured molds, and mass-produced a wide range of custom precision metal stamping parts using progressive dies for high-speed stamping, including:

• Wall switch copper parts: British, American, Australian, South African, European, and Italian series

• Home appliances: heat sinks, supports, and neutral/live contacts for various small appliances

• Mobile track sockets: A complete range of track socket and adapter parts

• Auto and motorcycle accessories: Seat connectors, brakes, and other parts for cars and motorcycles

• Electrical equipment: Factory high and low voltage cabinets, surge protectors, and low-voltage boxes

• Electronic lighting: Electronic components, electronic connectors, indoor and outdoor lighting

• Luggage: Home luggage, storage cases, lawn mower strap buckles, and luggage corner protectors

• Solar: Photovoltaic mounts, solar panel connectors, retaining washers, and rust-resistant rails

• Exterior steel structure: Exterior steel structure pendants made of aviation-grade materials

• Smart locks: smart lock accessories, single tongue locks, drawer locks, ball lock bodies

Equipment Capabilities

|

Pressure level |

Punching speed |

Maximum stamping stroke |

Maximum workbench length |

Maximum workbench width |

|

35T-200T |

Up to 1,50 beats per minute |

6 inches (152.40 mm) |

114 inches (2895.6 mm) |

33 inches (838.20 mm) |

Precision Stamping, Intelligent Manufacturing for the Future

Your one-stop metal stamping solution expert

Your one-stop metal stamping solution expert

English

English 中文

中文